Cool Tips for Reefer Container Shippers

Transporting chilled or frozen cargo in refrigerated containers is a rapidly growing industry with high demand. These containers ensure the safe and optimal preservation of perishable items such as meat, fish, fruit, dairy, and pharmaceuticals by maintaining regulated temperature and humidity, along with Controlled Atmosphere capabilities. Given the high value of these goods, securing their safe delivery throughout the cold chain is crucial.

Want to ensure you’re getting it right? Whether you’re a seasoned pro or new to the cold chain, mastering the stowing, stuffing, and loading process of your reefer container is key to maximizing efficiency and safety. From pre-cooling the goods to checking the container’s condition inside and out, we’ve compiled essential steps that set the stage for a successful and safe shipment.

Reefer Container Stowing

Properly stowing refrigerated containers is more than just a routine task; it’s crucial for maintaining the quality of temperature-sensitive goods. Each step of this process, from placing to securing, ensures that these containers remain stable and fully operational throughout the journey. This not only prevents damage but also guarantees that your valuable cargo remains at its peak quality.

One of the first rules of loading refrigerated containers is ensuring optimal airflow: Position these containers in areas of the vessel with easy access to power sources and ample ventilation. This way, your cargo stays at the perfect temperature, no matter how long the journey.

Weight distribution is another critical factor for maintaining the stability of the vessel. Unlike standard containers, which prioritize the efficient use of space and weight distribution, refrigerated containers come with an extra challenge: their built-in temperature-control machinery makes them significantly heavier.

While stowage planning is necessary for both dry and refrigerated goods, the complexity of stowing refrigerated goods demands a higher level of expertise.

Before stowing your reefer container, make sure that:

- The cargo has been pre-cooled to the required temperature.

- The container's external body and door gaskets are intact.

- The container is clean, odor-free, and in good condition, inside and out.

- The container's floor and grooves are clean and unobstructed.

- All four drainage openings are clear.

- All relevant data (stowage date, temperature, vessel, and voyage) has been accurately recorded on the chart and/or the ZIM sticker.

- The required temperature and air vent settings are clearly stated.

When stowing the container:

- Stow the cargo quickly and efficiently, keeping surface/pallet packing intact.

- Do not use a gas-powered forklift to stack surfaces/pallets, because its emissions can damage the cargo.

- Do not load any produce whose packing has been damaged during stowage.

- Check for and remove damaged fruit, because it can have a negative effect on the rest of the fruit in the container.

- The container should be opened as close as possible to the cold warehouse and the refrigeration unit should not be operated before or during stowing.

- Only activate the refrigeration unit after closing the container.

- Only the storage person (not a driver or anyone else) is authorized to lock the container with a security seal. The container seal number should be clear and legible and must remain covered.

In addition to their temperature control capabilities, reefer containers are built to be durable, secure, and easy to handle. These containers come equipped with security features, such as lockable doors and seals, to ensure that your goods remain protected during transit. However, it’s not just about securing the cargo – following proper safety measures when opening and closing refrigerated containers is equally critical. This helps prevent accidents and ensures compliance with industry standards and regulations.

Reefer Container Stuffing

The type of produce you’re shipping plays a significant role in the cargo being stuffed into the container.

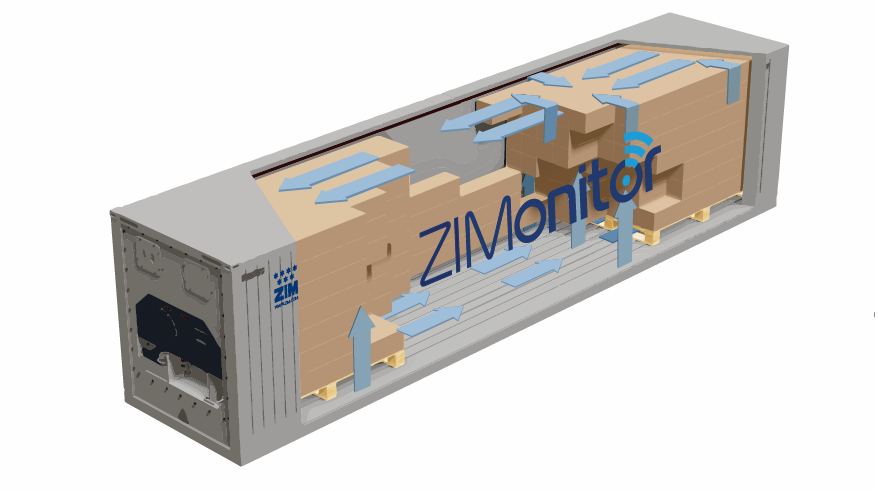

For chilled produce like fresh fruits and vegetables, it’s crucial to allow air to flow through the cargo to prevent the buildup of heat, carbon dioxide and other gases.

For frozen cargo, the priority shifts to ensuring a consistent flow of cold air around the goods to minimize temperature fluctuations.

Whether your shipments consist of fresh produce or frozen items, below are some useful tips to maintain proper air circulation within the refrigerated container.

To ensure uninterrupted airflow:

- Avoid loading beyond the edge of the T-Floor to maintain even airflow. Overloading may cause blockages and disruptions in the airflow, leading to temperature inconsistencies and potential spoilage of the goods being transported.

- Do not stow goods above the red line. These units are designed to have sufficient air space above the cargo to allow air to circulate back to the refrigerated unit. When goods are loaded beyond the red line, the space is blocked and hot air can become trapped, compromising the temperature control system.

- Do not leave excess space between cargo, in front of the door, and in front of the machinery.

- Double check that all air vents have been set to meet your requirements.

- Regularly check the temperature and humidity levels within the container to ensure that they are within the appropriate range for the type of cargo you are shipping.

Moving Reefer Containers

During transportation, whether at the terminal, during cold storage, or before loading the container onto the vessel, it’s essential to secure and monitor the refrigerated unit to maintain the integrity of the cool chain.

The safe movement of cargo relies on a few fundamental operational procedures designed to preserve an interrupted power supply, crucial for the safe transit of the cargo. These procedures don’t just apply during the initial loading but continue after the cargo reaches its destination and is transported by land to its final customer.

Before moving the container to the port or terminal, make sure that:

- The container is in good working order.

- The generator (if you have ordered one) is in good working order and the fuel tank is full.

- The temperature has been set correctly.

- Air vent openings have been set correctly.

- The container is sealed with a high security seal.

- Stickers have been applied as required.

- The driver has been instructed to check that the container is operating correctly throughout the land transportation leg, and to report any changes immediately to receive instructions.

When delivering the container at the port or terminal, the driver should check that:

- The container is in good working order throughout the waiting period at the entrance to the port/terminal.

- After discharge at the port/terminal, the container is immediately connected to a power source.

If you’re following these industry standards, you can ensure that the container is loaded properly, and the refrigeration system functions effectively throughout the entire voyage. Sticking to these practices not only protects your valuable cargo, but also minimizes the risk of spoilage or losses for both the shipper and the final customer.